Your Garment defects ppt images are available in this site. Garment defects ppt are a topic that is being searched for and liked by netizens now. You can Get the Garment defects ppt files here. Get all free images.

If you’re searching for garment defects ppt images information related to the garment defects ppt interest, you have pay a visit to the right site. Our website frequently gives you hints for seeking the highest quality video and image content, please kindly search and find more enlightening video content and images that fit your interests.

Garment Defects Ppt. Garment defects are also well known as reject the item. Awadhesh Kumar Choudhary Monica Puri Sikka and Payal Bansal. Defects in garments. Youll learn about more than 20 different quality defects related to garments and fabric that are typically found during pre-shipment product inspection.

Garment Defects From slideshare.net

Garment Defects From slideshare.net

PATENT DEFECTS b Premarking defects or marking the defects during spreading and recutting the defective garment piecescostly fabrics high labour cost. Nahian Mahmud Shaikat March 25 2018 July 19 2020 Apparel 29 Garments Defects All Garments defects Bartack Missing Brand Logo Mistake Broken Stitch Button Half Stitch common garments defects Damage. Department of Textile Technology Dr BR. Doctor Kaoru Ishikawa is best known for the development of the Fishbone also known as cause-effect diagramBrainstorm the major categories of causes of the problem fisbone works based on causes are Method Machine Manpower People Materials Measurement Management and Environment. Workmanship and Handling defects in garments. Garment Defects Garment defects can be separated into 3 categories.

Nahian Mahmud Shaikat March 25 2018 July 19 2020 Apparel 29 Garments Defects All Garments defects Bartack Missing Brand Logo Mistake Broken Stitch Button Half Stitch common garments defects Damage.

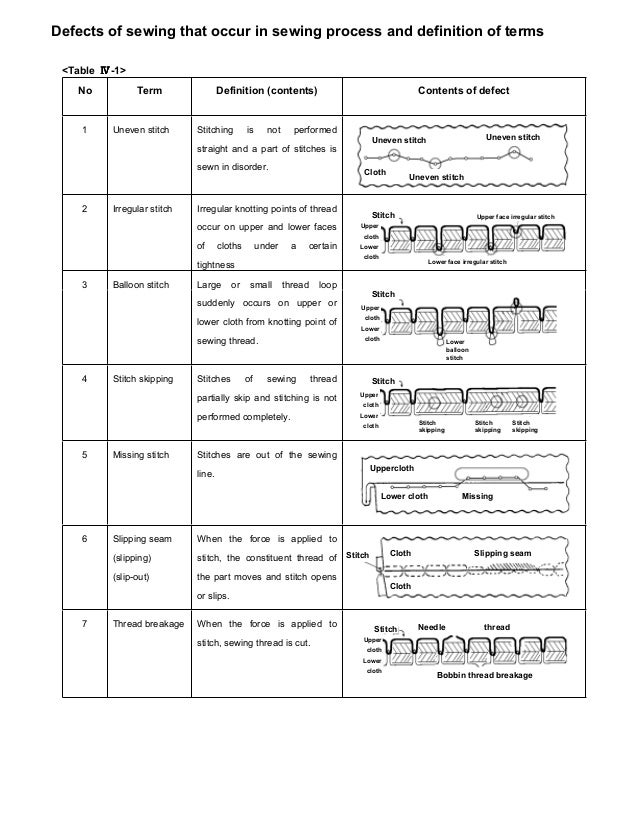

Stitching defects - Defects generated in garment stitching like a broken seam seam puckering skip stitches pattern mismatch etc. Youll also learn some of the common causes for these defects and how to prevent them. The stages of garment manufacturing- pattern making spreading cutting sewing assembling finishing and packaging involve a lot. Awadhesh Kumar Choudhary Monica Puri Sikka and Payal Bansal. Department of Textile Technology Dr BR. Defects in garments.

Source: seampedia.com

Source: seampedia.com

Ambedkar National Institute of. These are defects that are caused during the manufacture of the garment. Fabric flexibility proper alignment of two components joined together correct tension during sewing and slippage of fabric during garment manufacturing are some of the factors that limit the scope of automation in garment. Youll learn about more than 20 different quality defects related to garments and fabric that are typically found during pre-shipment product inspection. Approaching Zero Defect in manufacture of ready made garments.

Source: oursewingpattern.blogspot.com

Source: oursewingpattern.blogspot.com

Defects in garments. Pareto analysis and cause effect diagram are used in a. Diagram is easy to understand causes of defects of production. Ambedkar National Institute of. Textiles Committee FICCI Strategy Seminar.

In 1991 the import value of textiles was about 60 of the export value of Bangladesh-made clothing but this had fallen to 40 by 2001. C Removing the fabric defects. Youll learn about more than 20 different quality defects related to garments and fabric that are typically found during pre-shipment product inspection. Workmanship and Handling defects in garments. In textile industry woven fabric is produced by interlacing warp and weft yarn.

Source: pinterest.com

Source: pinterest.com

Awadhesh Kumar Choudhary Monica Puri Sikka and Payal Bansal. In 1991 the import value of textiles was about 60 of the export value of Bangladesh-made clothing but this had fallen to 40 by 2001. Workmanship and Handling defects in garments. At first it follows some easily possible main remedies and hence it reduces the defects as much as possible. C Removing the fabric defects.

Source: pinterest.com

Source: pinterest.com

Fabric flexibility proper alignment of two components joined together correct tension during sewing and slippage of fabric during garment manufacturing are some of the factors that limit the scope of automation in garment. If you have no idea of garments defects identification then it will be a tough job for you but if. Nahian Mahmud Shaikat March 25 2018 July 19 2020 Apparel 29 Garments Defects All Garments defects Bartack Missing Brand Logo Mistake Broken Stitch Button Half Stitch common garments defects Damage. Stitching defects - Defects generated in garment stitching like a broken seam seam puckering skip stitches pattern mismatch etc. Although not in the table the study cites Bangladesh as a country which has managed to achieve greater vertical integration through promot- ing a domestic textile industry.

Source: pinterest.com

Source: pinterest.com

Doctor Kaoru Ishikawa is best known for the development of the Fishbone also known as cause-effect diagramBrainstorm the major categories of causes of the problem fisbone works based on causes are Method Machine Manpower People Materials Measurement Management and Environment. Garment Defects Garment defects can be separated into 3 categories. MAA GarmentThis is a systematic approach towards defects minimization through five phases of DMAIC methodology named Define Measure Analyze Improve and Control which focuses on reductionelimination of four basic types of defects such as stain skip stitch broken stitch. Garment defects ppt. At first it follows some easily possible main remedies and hence it reduces the defects as much as possible.

Diagram is easy to understand causes of defects of production. MAA GarmentThis is a systematic approach towards defects minimization through five phases of DMAIC methodology named Define Measure Analyze Improve and Control which focuses on reductionelimination of four basic types of defects such as stain skip stitch broken stitch. Although not in the table the study cites Bangladesh as a country which has managed to achieve greater vertical integration through promot- ing a domestic textile industry. Garment defects - During manufacturing process defects could occur like faulty zippers irregular hemming loose buttons raw edges improper button. Youll also learn some of the common causes for these defects and how to prevent them.

Source: intouch-quality.com

Source: intouch-quality.com

Workmanship and Handling defects in garments. Shade variation within a garment Bar tack missing Placket placed center off Over lock stithes too loose Fabric wrinkles puckers at elastic binding Right side - Wrong size sleeve attached Color yarn contamination Broken stitches. Doctor Kaoru Ishikawa is best known for the development of the Fishbone also known as cause-effect diagramBrainstorm the major categories of causes of the problem fisbone works based on causes are Method Machine Manpower People Materials Measurement Management and Environment. Garment defects are also well known as reject the item. MAA GarmentThis is a systematic approach towards defects minimization through five phases of DMAIC methodology named Define Measure Analyze Improve and Control which focuses on reductionelimination of four basic types of defects such as stain skip stitch broken stitch.

Source: pinterest.com

Source: pinterest.com

Shade variation within a garment Bar tack missing Placket placed center off Over lock stithes too loose Fabric wrinkles puckers at elastic binding Right side - Wrong size sleeve attached Color yarn contamination Broken stitches. Garment defects - During manufacturing process defects could occur like faulty zippers irregular hemming loose buttons raw edges improper button. The stages of garment manufacturing- pattern making spreading cutting sewing assembling finishing and packaging involve a lot. Stitching defects - Defects generated in garment stitching like a broken seam seam puckering skip stitches pattern mismatch etc. Diagram is easy to understand causes of defects of production.

Source: pinterest.com

Source: pinterest.com

Garment defects ppt. Diagram is easy to understand causes of defects of production. Running shade selvedge to selvedge shade holes staining mark missing yarn foreign yarn slub hairiness etc. Awadhesh Kumar Choudhary Monica Puri Sikka and Payal Bansal. Pressing defects - Defects like shining water mark and incorrect pressing.

Source: pinterest.com

Source: pinterest.com

Nahian Mahmud Shaikat March 25 2018 July 19 2020 Apparel 29 Garments Defects All Garments defects Bartack Missing Brand Logo Mistake Broken Stitch Button Half Stitch common garments defects Damage. Approaching Zero Defect in manufacture of ready made garments. Running shade selvedge to selvedge shade holes staining mark missing yarn foreign yarn slub hairiness etc. Defects in garments. Garment defects ppt.

Source: slideshare.net

Source: slideshare.net

Ambedkar National Institute of. Garment defects are also well known as reject the item. These are defects that are found in the fabric mostly these are not caused by the sewing lines. Workmanship and Handling defects in garments. Garment Defects Garment defects can be separated into 3 categories.

Source: pinterest.com

Source: pinterest.com

Department of Textile Technology Dr BR. The stages of garment manufacturing- pattern making spreading cutting sewing assembling finishing and packaging involve a lot. Garment defects ppt. Awadhesh Kumar Choudhary Monica Puri Sikka and Payal Bansal. Garment defects are also well known as reject the item.

Source: intouch-quality.com

Source: intouch-quality.com

In textile industry woven fabric is produced by interlacing warp and weft yarn. Garment Defects Garment defects can be separated into 3 categories. Awadhesh Kumar Choudhary Monica Puri Sikka and Payal Bansal. If you have no idea of garments defects identification then it will be a tough job for you but if. Pareto analysis and cause effect diagram are used in a.

Source: pinterest.com

Source: pinterest.com

Fabric flexibility proper alignment of two components joined together correct tension during sewing and slippage of fabric during garment manufacturing are some of the factors that limit the scope of automation in garment. Although not in the table the study cites Bangladesh as a country which has managed to achieve greater vertical integration through promot- ing a domestic textile industry. At first it follows some easily possible main remedies and hence it reduces the defects as much as possible. Running shade selvedge to selvedge shade holes staining mark missing yarn foreign yarn slub hairiness etc. MAA GarmentThis is a systematic approach towards defects minimization through five phases of DMAIC methodology named Define Measure Analyze Improve and Control which focuses on reductionelimination of four basic types of defects such as stain skip stitch broken stitch.

Source: pinterest.com

Source: pinterest.com

Doctor Kaoru Ishikawa is best known for the development of the Fishbone also known as cause-effect diagramBrainstorm the major categories of causes of the problem fisbone works based on causes are Method Machine Manpower People Materials Measurement Management and Environment. Fabric flexibility proper alignment of two components joined together correct tension during sewing and slippage of fabric during garment manufacturing are some of the factors that limit the scope of automation in garment. Pareto analysis and cause effect diagram are used in a. In 1991 the import value of textiles was about 60 of the export value of Bangladesh-made clothing but this had fallen to 40 by 2001. Defects in garments.

Stitching defects - Defects generated in garment stitching like a broken seam seam puckering skip stitches pattern mismatch etc. Textiles Committee FICCI Strategy Seminar. These are defects that are found in the fabric mostly these are not caused by the sewing lines. Running shade selvedge to selvedge shade holes staining mark missing yarn foreign yarn slub hairiness etc. Garment Defects Garment defects can be separated into 3 categories.

Source: slideshare.net

Source: slideshare.net

In textile industry woven fabric is produced by interlacing warp and weft yarn. Department of Textile Technology Dr BR. MAA GarmentThis is a systematic approach towards defects minimization through five phases of DMAIC methodology named Define Measure Analyze Improve and Control which focuses on reductionelimination of four basic types of defects such as stain skip stitch broken stitch. Garment Defects Garment defects can be separated into 3 categories. Textiles Committee FICCI Strategy Seminar.

This site is an open community for users to submit their favorite wallpapers on the internet, all images or pictures in this website are for personal wallpaper use only, it is stricly prohibited to use this wallpaper for commercial purposes, if you are the author and find this image is shared without your permission, please kindly raise a DMCA report to Us.

If you find this site adventageous, please support us by sharing this posts to your preference social media accounts like Facebook, Instagram and so on or you can also bookmark this blog page with the title garment defects ppt by using Ctrl + D for devices a laptop with a Windows operating system or Command + D for laptops with an Apple operating system. If you use a smartphone, you can also use the drawer menu of the browser you are using. Whether it’s a Windows, Mac, iOS or Android operating system, you will still be able to bookmark this website.