Your Garment defect zones images are ready in this website. Garment defect zones are a topic that is being searched for and liked by netizens now. You can Download the Garment defect zones files here. Find and Download all royalty-free photos and vectors.

If you’re looking for garment defect zones images information related to the garment defect zones topic, you have come to the right site. Our website always provides you with suggestions for viewing the maximum quality video and picture content, please kindly hunt and locate more enlightening video content and images that match your interests.

Garment Defect Zones. We already know that all types of defects of apparel or garments products are classified into three defects group. We can further classify garments defects into the following categories. Missing of any parts or predetermined design of garments. Performance of a garment must be taken into consideration.

How To Classify Garment Defects Abc Seams From abcseams.com

How To Classify Garment Defects Abc Seams From abcseams.com

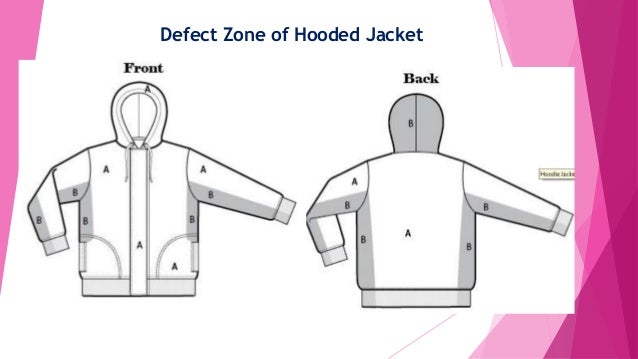

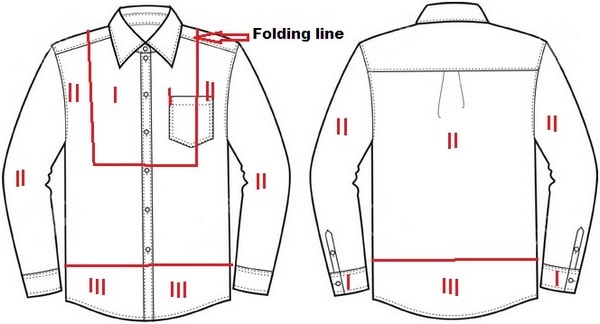

Scorching or burn marks. Defect Zone Classification of Garments during Visual Inspection. After wash streak or striation 115. Front center of back upper side of sleeve upper side of collar. Garment zoning is done for fair evaluation of the garment during the visual audit. Button hook and so on in the proper place.

Visual defects are categorized as Major Minor and Critical defects.

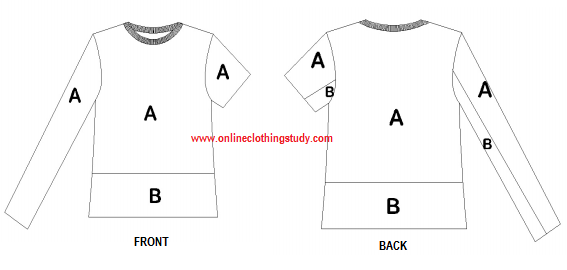

Chalk pen or pencil marks visible 118. This location is called as a zonegarment zoning. A garment can be divided up to 3 zones like A B and C. Appearance Zones of the garment - The defects listed below are defects rated by two areas of the garment Zone A and Zone B. Zero Tolerance Zero Tolerance covers the entire garment and applies to any sharp objects or a chemical product. Front center of back upper side of sleeve upper side of collar.

Source: slidetodoc.com

Source: slidetodoc.com

Front center of back upper side of sleeve upper side of collar. We can further classify garments defects into the following categories. Một số comments về màu sắc. Use of the wrong ticket. A garment can be divided up to 3 zones like A B and C.

Source: sciencedirect.com

Source: sciencedirect.com

Size and severity also have an impact on the acceptability. Care label fading damage after wash 117. These defects created in garments manufacturing actually occur at the time of product construction. Visual defects are categorized as Major Minor and Critical defects. And together with the AQL it helps to determine if the inspection is approved or not.

The obvious area of the garments include the whole collar placket pocket and upper part of the garments in where any kind of fault can be appeared easily is called Zone-A. Defect classification is an important step in determining whether goods should pass or fail to inspect and it helps to take an informed shipping decision by considering the quantification and severity of various types of defects identifiedClassification of garments defects. In some cases a major defect can be considered as minor based on the location of the defect in a garment. A garment is divided into 3 zones. Appearance not smooth 121.

Source: intouch-quality.com

Source: intouch-quality.com

G tham khảo nhé. Imperfect alignment of components ie. Use of the wrong ticket. Performance of a garment must be taken into consideration. Most noticeable Zone- II.

Source: slideshare.net

Source: slideshare.net

Scorching or burn marks. In some cases a major defect can be considered as minor based on the location of the defect in a garment. ZONE A areas of the garment that will draw attention. Performance of a garment must be taken into consideration. Scorching or burn marks.

Source: seampedia.com

Source: seampedia.com

Most noticeable Zone- II. Visual defects are categorized as Major Minor and Critical defects. Zero Tolerance Zero Tolerance covers the entire garment and applies to any sharp objects or a chemical product. Most noticeable Zone- II. The Garment Defects Classification is also used as a supporting document for inspection reports.

Source: smartchinasourcing.com

Source: smartchinasourcing.com

Any deviation from customer requirement or standard we can call it to defect. Button hook and so on in the proper place. Missing of any parts or predetermined design of garments. Garments Defects is something we call imperfection the incompleteness of a Garments product. And together with the AQL it helps to determine if the inspection is approved or not.

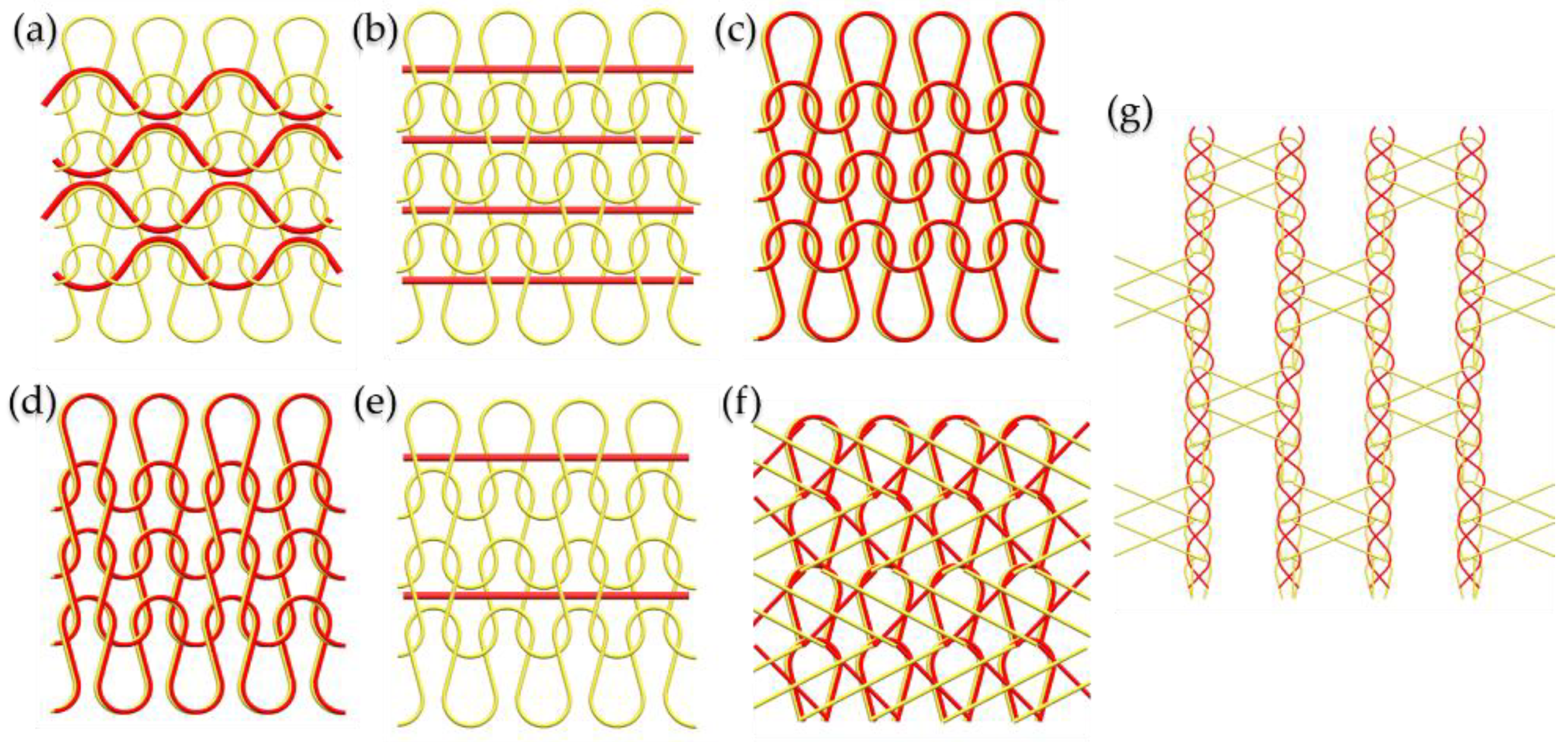

Source: mdpi.com

Source: mdpi.com

In some cases a major defect can be considered as minor based on the location of the defect in a garment. Any deviation from customer requirement or standard we can call it to defect. Button hook and so on in the proper place. ZONE A areas of the garment that will draw attention. This location is called as a zonegarment zoning.

Source: slidetodoc.com

Source: slidetodoc.com

Một số comments về màu sắc. Missing of any parts or predetermined design of garments. Our standard defect classification for all merchandising categories. Back staining of pocket 116. G tham khảo nhé.

Source: onlineclothingstudy.com

Source: onlineclothingstudy.com

In society to comport inspection garments are divided into a number of zones. Front center of back upper side of sleeve upper side of collar. Missing of any parts or predetermined design of garments. Defect classification is an important step in determining whether goods should pass or fail to inspect and it helps to take an informed shipping decision by considering the quantification and severity of various types of defects identifiedClassification of garments defects. Garment Zoning A garment can be divided into 3 zones like A B and C.

Appearance not smooth 121. Zoning is done for fair evaluation of the garment during visual audit. We can further classify garments defects into the following categories. Performance of a garment must be taken into consideration. And together with the AQL it helps to determine if the inspection is approved or not.

Source: sosopoetry.blogspot.com

Source: sosopoetry.blogspot.com

Front center of back upper side of sleeve upper side of collar. Garments Defects is something we call imperfection the incompleteness of a Garments product. ZONE A areas of the garment that will draw attention. Missing of any parts or predetermined design of garments. Chalk pen or pencil marks visible 118.

Source: oursewingpattern.blogspot.com

Source: oursewingpattern.blogspot.com

Garment defects caused in the Finishing and Washing process 114. Garments Defects is something we call imperfection the incompleteness of a Garments product. Zero Tolerance Zero Tolerance covers the entire garment and applies to any sharp objects or a chemical product. 4 Minor defects - 1 Major Defect. Appearance Zones of the garment - The defects listed below are defects rated by two areas of the garment Zone A and Zone B.

Source: autogarment.com

Source: autogarment.com

The obvious area of the garments include the whole collar placket pocket and upper part of the garments in where any kind of fault can be appeared easily is called Zone-A. Garment defects caused in the Finishing and Washing process 114. G tham khảo nhé. Một số comments về màu sắc. After wash streak or striation 115.

Source: seampedia.com

Source: seampedia.com

We can further classify garments defects into the following categories. ZONE A areas of the garment that will draw attention. A garment can be divided up to 3 zones like A B and C. Garment defects - During manufacturing process defects could occur like faulty zippers irregular hemming loose buttons raw edges improper. Visual defects are categorized as Major Minor and Critical defects.

Source: intouch-quality.com

Source: intouch-quality.com

Garments Defects is something we call imperfection the incompleteness of a Garments product. Average noticeable Zone- III. These defects created in garments manufacturing actually occur at the time of product construction. Fabric Appearance Color Shade Workmanship Construction Cleanliness and Packing is classified using zones. Visual defects are categorized as Major Minor and Critical defects.

Source: mirisys.com

Source: mirisys.com

Appearance Zones of the garment - The defects listed below are defects rated by two areas of the garment Zone A and Zone B. 4 Minor defects - 1 Major Defect. Appearance Zones of the garment - The defects listed below are defects rated by two areas of the garment Zone A and Zone B. This location is called as a zonegarment zoning. Appearance Zones of the garment - The defects listed below are defects rated by two areas of the garment Zone A and Zone B.

Button hook and so on in the proper place. Back staining of pocket 116. Garments Defects is something we call imperfection the incompleteness of a Garments product. Chalk pen or pencil marks visible 118. Button hook and so on in the proper place.

This site is an open community for users to do sharing their favorite wallpapers on the internet, all images or pictures in this website are for personal wallpaper use only, it is stricly prohibited to use this wallpaper for commercial purposes, if you are the author and find this image is shared without your permission, please kindly raise a DMCA report to Us.

If you find this site serviceableness, please support us by sharing this posts to your favorite social media accounts like Facebook, Instagram and so on or you can also save this blog page with the title garment defect zones by using Ctrl + D for devices a laptop with a Windows operating system or Command + D for laptops with an Apple operating system. If you use a smartphone, you can also use the drawer menu of the browser you are using. Whether it’s a Windows, Mac, iOS or Android operating system, you will still be able to bookmark this website.